Fig 1. Bed bent up.

Fig 2. Relief for bed casting.

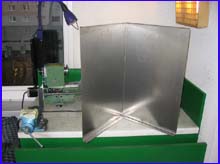

Fig 3. Cover open.

Fig 4. Cover closed, making end template.

Enclosure

Base and Cover

Got some 0.75mm mild steel sheet from the local hardware store, marked it out and had the the sheet metal shop at work guillotine and bend it. (Fig 1.)

The flanges are 20mm high, which means a cut out had to be made to clear the lathe bed casting. (Fig 2.)

The Cover is made of two pieces of perspex and one of steel sheet. There are therefore three piano hinges. I did it this way so that the lid has a nice angled window above the tool post, and yet will sit open against the wall. (Fig 3)

The the hinges are bolted to the perspex and sheet with 3mm countersunk screws. I overtightened many of the screws and caused the perspects to crack a couple of days after assembly. Have to redo the windows.