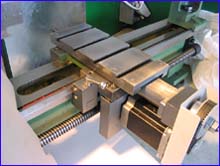

7X12 Mini-Lathe T-slotted Cross-slide.

Final Assembly

Assemble the whole slide dry, blue up the headstock side dovetail surface and do a test install on the saddle. Check whether the gib can be inserted. On mine the gib would not go all the way in, so th etailstock side dovetail piece was removed and filed a little, then relapped. The the blueing of the headstock side dovetail showed very even contact over nearly all it's surface, and needed no further work.

Once you are satisfied with the fit up, disassemble it all for a final de-grease and deburr. I choose to epoxy mine together (belt and suspenders). All expoxied surfaces where roughed with 80 grit emery cloth. The expoxy was branded UHU, but I think it is rebranded Araldite 2011 from the spec's. With a two hour working time, you have time to get every thing well coated and assembled. Take the time to wipe the excess epoxy out of the T-slots and dovetails, it is a lot harder to remove once set. I baked the assembly at 75°C for 45 min's as per the instructions. This increases bond strength to around 2kN/cm².

Milling the slide was straight forward, except the mill backed out of the collet, which was not tight enough - I hate working under pressure in someone elses workshop. This guaged the side towards the tailstock. I ended up milling the width of the table to 72mm which gave the benefit of being able to use the original gib screws.