Fig. 1 Before.

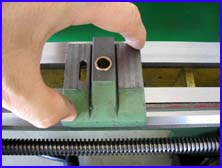

Fig. 2 Rocking.

Fig. 3 Addressing the rock.

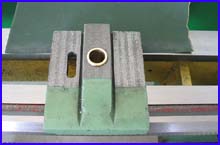

Fig .4 After lapping.

Lathe Alignment Check

Tailstock

The Tailstock on these lathes really lets down the otherwise suprisingly good quality. The one from my lathe is similar to that described by Rick Kruger.

A few months ago I put a brass bush into the hole in the base plate as you have a 12mm hole with a 10mm bolt going through, and the bolt keeps canting and then the locking plate catches on the bed. The bushing helped a little, but I still need to make the lever lock mod.

Rick also developed a good mod to allow controlled, repeatable set over of the tailstock. As a CNC lathe is capable of machining tapers directly, I have no plans to ever set over the tailstock. My goal is to shim the tail stock base to body interface until it is on center, then expoxy the whole works together so that it never moves again :)

Fig. 1 Shows the bottom as delivered. Rough as guts, some half-arsed scraping.

Fig.2. The base rocked noticeably across these two corners.

Fig. 3. There was no point doing anything more with this until it could sit flat. It didn't take much to flatten it, just a few swipes across a peice of 600 grit wet and dry sitting on the rear way. If my tailstock is anything like Rick Kruger's, this process will have a 50:50 chance of improving overall alignment.

Fig. 4 As you can see, I made no attempt to get good contact over the whole slide. At least it now sits on the bed without rocking.